WHAT IS R-VALUE?

FIBERGLASS VS CELLULOSE BLOWN-IN INSULATION

BEST BLOWN-IN ATTIC INSULATION

BLOWN-IN

HOME INSULATION NEEDS

WHAT IS R-VALUE?

R-value is a measure of thermal resistance.

When checking the effectiveness of insulation. R-Value indicates how well a material resists heat flow. The higher the R-values mean the better insulating properties.

When selecting insulation, consider the R-value to ensure your home is energy-efficient and comfortable.

Key Points about R-Value:

Heat Resistance: The R-value measures how well a building material insulates against heat loss in winter and heat gain in summer.

Units: R-values are typically expressed in square feet, hours, and degrees Fahrenheit (ft²·°F·h/Btu).

Material Differences: Different materials have different R-values. For example, fiberglass insulation generally has a higher R-value than cellulose insulation.

Thickness Matters: The R-value increases with the thickness of the insulation; thicker materials provide better insulation.

Application: R-values are crucial for energy efficiency in homes and buildings, impacting heating and cooling costs.

We offer free insulation quotes for Sprayfoam insulation & Blow-In Insulation.

AG BUILDINGS

COMMERCIAL

HOME

GARAGE

Factors Affecting Insulation R-Value

The R-value of insulation refers to its ability to resist heat flow. With higher R-values indicating better insulating performance.

Just because the insulation says its R-60 doesn’t necessarily mean that’s what you are going to get once it is installed.

Several factors can affect the R-value of insulation, including material type, thickness, and environmental conditions. Here are the main factors:

1. Material Type

- Different insulation materials have varying inherent R-values. For example, closed-cell spray foam has a much higher R-value per inch (R-6.0 to R-6.5) compared to fiberglass batts (R-2.9 to R-4.3 per inch).

- Materials like cellulose and mineral wool have intermediate R-values, while reflective barriers don’t have a traditional R-value but affect heat transfer by reflecting radiant energy.

2. Thickness of the Insulation

- R-value increases with the thickness of the insulation material. For example, doubling the thickness of fiberglass insulation will approximately double its R-value.

- Some materials, like spray foam, require less thickness to achieve a high R-value compared to others like blown-in cellulose.

3. Insulation Density

- The density of the insulation material impacts the R-value. Denser materials (e.g., closed-cell spray foam) tend to have higher R-values because they trap more air and resist heat flow better.

- If insulation is too loosely packed (e.g., blown-in insulation), it may lose some effectiveness and have a lower R-value.

4. Installation Quality

- Proper installation is critical to achieving the intended R-value. Gaps, voids, and compressed insulation reduce its effectiveness and lower the R-value.

- Misalignments or areas where the insulation doesn’t fully cover the space can create thermal bridges, where heat easily escapes, reducing overall insulation performance.

5. Moisture and Humidity

- Insulation that becomes wet or absorbs moisture (e.g., fiberglass or cellulose) can lose R-value. Wet insulation conducts heat more easily and can lead to mold growth.

- Vapor barriers or proper moisture control strategies are necessary in some climates to prevent insulation from getting damp and losing effectiveness.

6. Temperature Variations

- Some insulation materials may see a decrease in R-value in extreme temperatures. For example, the R-value of fiberglass insulation can diminish in very cold temperatures because trapped air pockets may not function as effectively.

- Closed-cell spray foam performs well even in extreme temperatures, retaining its insulating properties.

7. Settling Over Time

- Loose-fill insulation materials like cellulose or fiberglass can settle over time, reducing the thickness and, therefore, the R-value.

- This factor is less of a concern for batt insulation or spray foam, which maintain their structure over time.

8. Air Movement and Drafts

- Air leakage or drafts can reduce the effective R-value of insulation. Even high R-value materials will not perform well if there are significant air leaks around or through the insulation.

- Spray foam insulation, for example, also acts as an air barrier, maintaining its effectiveness better than insulation that is air-permeable, like fiberglass batts.

9. Thermal Bridging

- R-value can be affected by thermal bridging, where heat flows through materials with lower R-values, such as wood framing or metal studs, bypassing the insulation.

- Reducing thermal bridging through advanced framing techniques or continuous insulation can improve the overall performance of an insulated space.

10. Compression

- Compressing insulation reduces its thickness and air-trapping ability, thereby lowering its R-value. Fiberglass batts, for example, should be installed at their full thickness to perform effectively.

By considering these factors and ensuring proper installation, the insulation will achieve its maximum R-value and contribute to energy efficiency and comfort in the building.

Recommended Attic Insulation Thickness

The thickness of the insulation of an attic varies according to two main factors:

- the R Value of the insulation, and

- the material used as insulation.

This is because, as far as the insulation material. More or less may insulation is needed to achieve the desired R-Value in the attic.

As for the R Value, the higher it is, the more insulation required.

Usually, the recommended R-Value for attics varies between R 40 and R 80. Depending on the area, province and climate. The thickness must be suitable to meet the needs of R Value. The thickness of insulation which fluctuates according to the type of insulating material,

Here is the recommended thickness for the insulation of the penthouses based on the R Value:

- R 40: Thickness that oscillates between 13 and 15 inches.

- R 50: Thickness that oscillates between 15 and 19 inches.

- R 60: Thickness that oscillates between 19 and 22 inches.

- R 70: Thickness that oscillates between 22 and 25 inches.

- R 80: Thickness that oscillates between 25 and 28 inches.

The calculation is based on the thickness of insulation. Which is usually one inch for each R 3 of R Value.

Factors to Consider When Choosing Attic Insulation in Canada:

- Climate Zone: Cold climates need higher R-values (typically R-50 to R-60 in the attic).

- Moisture Control: Proper vapor barriers and air sealing are crucial in humid areas or in homes with attic moisture issues.

- Budget: Some options, like fiberglass, are more affordable, while others like spray foam provide better performance but at a higher cost.

- Energy Efficiency Goals: Higher R-values and air-sealing properties improve energy efficiency and lower heating costs.

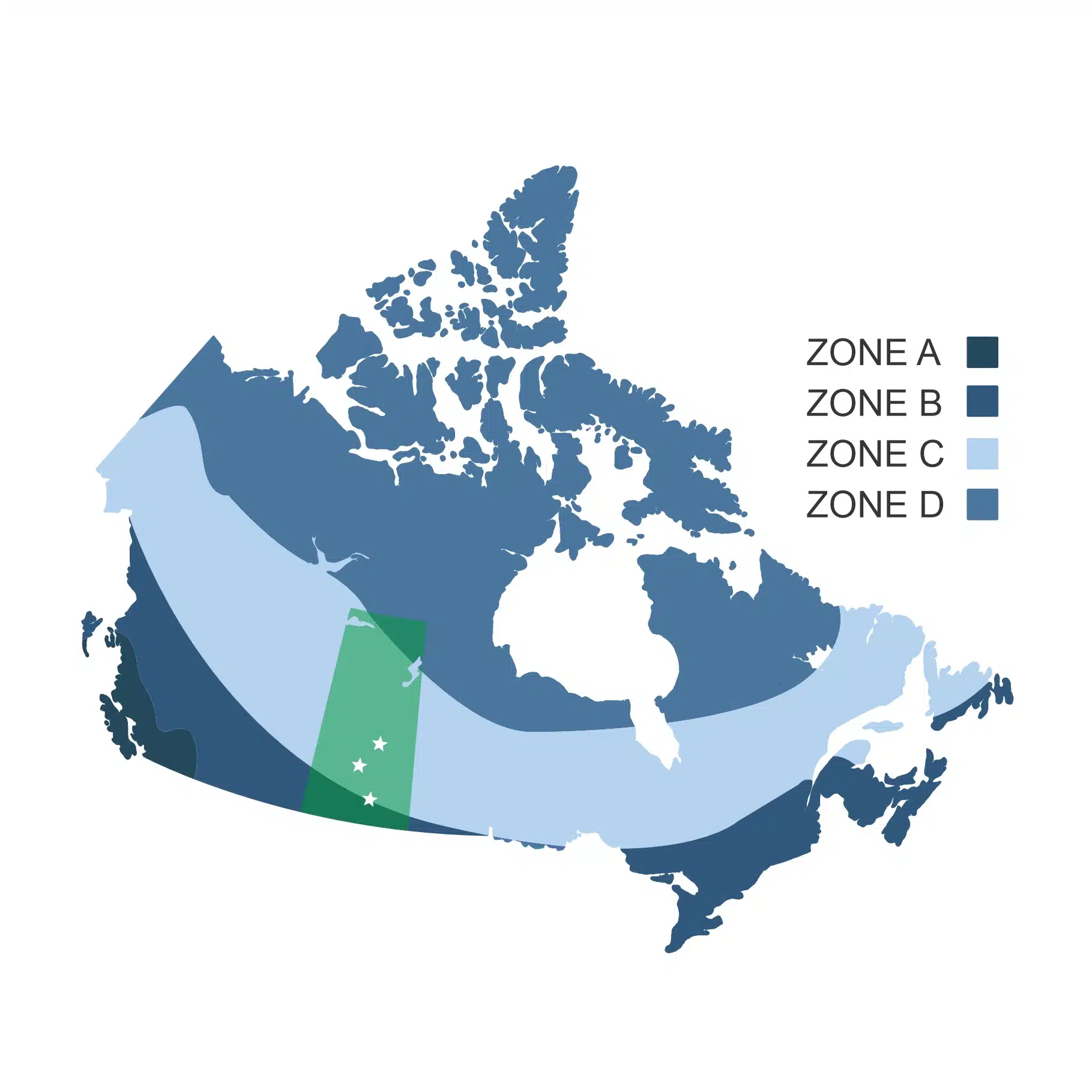

Saskatchewan is comprised of 3 Climate Zones. Zones B, C and D. Regina, Saskatoon and Prince Albert are all in Zone C.South of Regina, it is Zone B. Where the northeastern part of Saskatchewan is Zone D.

In Saskatchewan, where homes need to withstand colder temperatures. It’s crucial to choose the right attic insulation.

There are 4 common types of attic insulation, each with distinct characteristics:

Fiberglass Batt Insulation

- Material: Fiberglass

- R-Value: R-2.9 to R-4.3 per inch

- Pros:

- Easy to install.

- Affordable and widely available.

- Resistant to moisture and fire.

- Cons:

- Can lose effectiveness if not properly installed.

- Dust and fibers can be irritating to skin and lungs.

Blown-In Fiberglass Insulation

- Material: Loose fiberglass fibers

- R-Value: R-2.2 to R-2.7 per inch

- Pros:

- Good for filling small spaces or hard-to-reach areas.

- Quick to install with proper equipment.

- Cons:

- Requires specialized equipment for installation.

- Settling over time may reduce its effectiveness.

Blown-In Cellulose Insulation

- Material: Recycled paper products treated with fire retardant

- R-Value: R-3.1 to R-3.7 per inch

- Pros:

- Environmentally friendly (made from recycled materials).

- Good thermal performance.

- Helps reduce air leaks.

- Cons:

- Can absorb moisture if exposed, leading to mold or rot.

- Settles over time, requiring top-ups.

Spray Foam Insulation

- Material: Polyurethane foam

- R-Value (Open-Cell): R-3.5 to R-3.6 per inch

- R-Value (Closed-Cell): R-6.0 to R-6.5 per inch

- Pros:

- Excellent air sealing properties.

- Closed-cell spray foam is moisture resistant.

- High R-value, requiring less thickness for effective insulation.

- Cons:

- Expensive compared to other options.

- Requires professional installation.

- Closed-cell is not ideal for areas with slight movement, as it can crack.

Break down your Insulation project into smaller, manageable payments with financing.

We’ve partnered with Finance-It to offer you affordable monthly payment options. The application process only takes a few minutes and you’ll find out if you’re approved in seconds.

Financeit is the effortless, mobile-friendly way to pay for large purchases in low installments.

Greener Solutions Spray Foam is properly suited for all types of spray polyurethane foam insulation jobs.

From pole barns, shops, and quonsets to storage tanks, commercial buildings or even crawl spaces it is the proven best solution for you.

Greener Solutions provides services in Sprayfoam and Blown-in Insulation.

We service all areas in Saskatchewan.

Saskatoon & Regina Insulation Company

Spray Foam Insulation & Blown-In Insulation Companies

We’ve partnered with Finance-It to offer you affordable monthly payment options. The application process only takes a few minutes and you’ll find out if you’re approved in seconds.

Finance-It uses bank-level encryption to protect your personal information. Finance-It also provides a fair and transparent experience.